TOP SAFETY PERFORMANCE IN 2020

We routinely measure the effectiveness of our safety efforts, such as personal and process safety; health, environmental, safety and security (HES&S) training; workforce health; and emergency preparedness and response.

“Last year, COVID-19 was a rapidly-emerging threat and we responded by implementing controls to ensure the safety of our workforce. We stood up a 60-person COVID-response team who worked around the clock to oversee the safety of our operations. I’m proud that our response to the pandemic was strong and even prouder that we did it without sacrificing our other safety programs or safety culture. This speaks to the strength of our HES culture.” – Jon Kizzee, Corporate Health & Safety Manager

Marathon Oil’s HES&S activities are guided by our Responsible Operations Management System (ROMS), which includes HES&S Standards, Procedures, Life Critical Expectations and HES Beliefs. The HES Beliefs define Stop Work Authority, pre-job planning, reporting and sharing lessons learned, and open communication. They affirm that no job will be performed if we cannot protect our people.

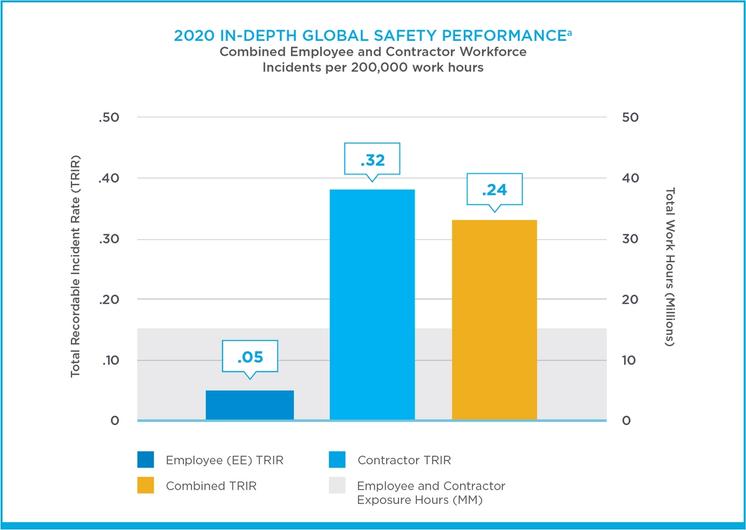

In 2020, we again had zero fatalities and achieved the best safety performance in our company’s history for the second consecutive year. Our combined TRIR for both employees and contractors declined to 0.24 in 2020 compared to 0.32 in 2019. We believe the maturity of our safety culture and ROMS were primary factors, with ROMS continuing to drive improvements through standards and procedures, leadership engagements, risk assessments and other essential safety activities.

SECTION 2

Safety Metrics

OVERVIEW

Below are highlights of our 2020 safety performance.

Safety Performance

Combined Employee and Contractor Workforce (Incidents x 200,000/Work Hours)TRIR2016201720182019202000.20.40.60.8GLOBAL SAFETY PERFORMANCEa

- ᵃ TRIR = Incidents x 200,000 / Work Hours.

Maintaining a Robust Reporting Culture

We believe that Marathon Oil has a strong and transparent reporting culture, which is encouraged by our leadership. All employees and contractors are trained on our processes and required to report all incidents, including “near misses.” A near miss is an unplanned or uncontrolled event or chain of events that didn’t result in a recordable injury, illness, physical damage or environmental damage, but had the potential to do so in other circumstances.

We evaluate and track all near misses with the intent of preventing them from becoming actual events. In 2020, our near miss frequency rate was approximately 16.7. We also expanded the definition of a near miss in 2020 to include unlit flare events and other air releases that have no actual regulatory impact.

We continue to strive to improve our process safety performance

Process Safety

Process safety encompasses programs to prevent hydrocarbon releases that have the potential to affect people, property and the environment. It means designing and maintaining our facilities so they work as intended, thus striving to protect our employees and the communities where we operate. These programs include our design and construction standards, mechanical integrity, safe work practices, operating procedures and management of change.

In 2020, Marathon Oil completed a targeted, in-depth audit of our process hazard analyses (PHAs), which are used to assess process safety-related risks. We are committed to auditing the PHAs at least every three years.

In 2020, we also strengthened our focus on process safety through the development of process safety awareness training and advanced level training. In addition, we worked to standardize our process safety procedures across our business units and improved the quality of our Hazardous Operations (HAZOP) assessments, a multi-day assessment which aims to prevent process safety events. We completed two of these assessments in 2020, one of which was conducted virtually due to the pandemic. To maintain high quality assessments, we use third-parties with expertise in the HAZOP methodology to lead the assessments as we identify risks and appropriate safeguards, such as alarms and relief devices.

We continue to strive to improve our process safety performance, track and investigate process safety incidents and near misses, develop corrective actions and share them throughout the company. Process safety events (PSEs) are classified using the American Petroleum Institute’s Recommended Practice 754. In 2020, we experienced 0 Tier 1 (high-consequence) or Tier 2 (medium-consequence) PSEs at our designated facilities in our U.S. resource plays, Marathon EG Production Limited (MEGPL) and Equatorial Guinea LNG Operations, S.A. (EG LNG).

Road Safety

Our commitment to safety extends to road safety. We utilize industry standards, evaluate and implement improvements to our systems, and continually train employees on best practices. An important component of managing safe and responsible transport is leveraging technology and data. We use real-time vehicle tracking and monitoring and have installed GPS devices on all company vehicles. The data allows us to monitor employee performance and intervene if deficiencies are identified.

Our Driving Safety Standard reinforces existing Marathon Oil rules to wear seat belts and drive within the speed limit, as well as prohibits the use of mobile communication devices while driving. It also sets minimum requirements for driver qualification and fitness, vehicle safety devices, security, company vehicle specifications, maintenance and inspection, removal of driving distractions, event reporting and investigation, journey management and driving in challenging international locations. All employees who drive a vehicle for company business are required to take driving safety awareness-level training.

Reinforcing our rules and expectations for safe driving

SECTION 3

Contractor Safety

HOLDING OUR CONTRACTORS ACCOUNTABLE

Marathon Oil’s goal is to work with top-rated contractors who share our commitment to safeguarding our workforce, communities, property and the environment.

The strong relationships we build with our contractor workforce can help to prevent fatalities, injuries, fires, spills or explosions that can affect our people and our communities. We take a risk management-based approach to contractor oversight and provide safety-based orientation to all new contractors and companies when they begin to work with us.

We hold suppliers accountable for executing our required Life Critical Expectations training and safety orientation programs, complying with our safety policies and adhering to our contractor management plans. While we strive to maintain a stable contractor workforce, we will stop working with vendors who don’t meet our HES expectations and performance requirements.

In addition, we conduct field-based safety inspections and audits, track our contractors’ OSHA recordables and serious event rate, and oversee our contractors in line with the ROMS Third-Party Services element.

Marathon Oil leverages Safety Leadership Engagements to convey our safety culture, expectations, preventive measures and work requirements such as our Life Critical Expectations and Stop Work Authority. Despite the ongoing pandemic, we remained committed to conducting safety leadership engagements in 2020 by shifting to virtual formats.

We also continued to enforce our contractor safety requirement process, which bars individuals from working on all Marathon Oil locations if they fail to follow our drug and alcohol policy, or knowingly violate our Life Critical Expectations. These individuals are identified by a red flag in ISNetworld, and contractors aren’t allowed to perform work onsite if the red flag appears when their badge is scanned at a Marathon Oil location.

In 2020, we launched an all-virtual version of Marathon Oil’s Life Critical Expectations training prior to the pandemic. Approximately 9,300 individual contractors successfully completed the online training and passed the associated safety exam.

Our Life Critical Expectations

Our 10 Life Critical Expectations are the core of our safety program, and our leadership is committed to communicating and mandating that these standards are followed. These expectations address personal safety hazards that can result in serious injuries, or even fatalities if not properly managed. All of our operating organizations adopt and follow the Life Critical Expectations that are relevant to their operations and the type of work they perform. We expect our contractors to have equivalent programs in place that at least meet our safety expectations and hold all employees and contractors accountable to these standards.

Source: Marathon Oil

Oil & Gas Operators